TEN350 The waveform that hijacked the IEC lightning standards

Spark Gap Challenge

Background to the challenge

In 2010-2011 lightning scientists at the Conghua Triggered Lightning Laboratory in Guangdong, China, made a disturbing discovery: European surge protectors were being damaged when subjected to measured lightning well below their promoted rating. For example, an SPD rated at 40kA was damaged by a 2kA lightning surge. Several papers were written about this phenomenon. One presented at the 2011 International Conference on Atmospheric Engineering (ICAE) can be found here. The scientists concluded that actual lightning must be causing far more stress to SPDs than the single impulse 10/350 testing procedures required by lightning protection standards. They decided to test their hypothesis by devising a test that would employ the parameters they'd observed and measured in their triggered lightning experiments. The key parameter was considered to be the multiple-impulse aspect of lightning, but they also specified Ipeaks, length of the waveshape tail, and interstroke intervals. They arranged for this test set-up to be established at the Beijing SPD Test Laboratory. (北京雷电防护装置测试中心) And they then set the date for the test.

The Original Challenge: 2011.

Over a dozen SPD manufacturers were invited to attend the world’s first multiple-impulse test challenge, held in December 2011 at the Beijing SPD Test Laboratory. The manufacturers included famous-name European spark gap manufacturers and an American manufacturer of MOV-type SPDs.

Although not known at the time, the test parameters chosen for that test were amazingly consistent with those legitimized by CIGRE's 2013 Technical Brochure 549.

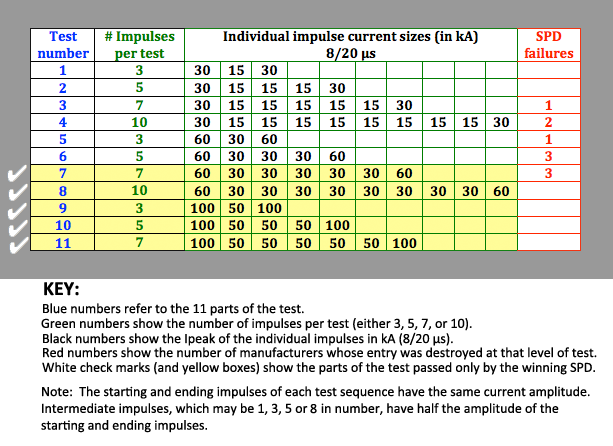

11 manufacturers participated in the 2011 challenge, each submitting one SPD. The test was designed to subject each of the SPDs (whether spark gap or MOV-based) to the same 11-part series of multiple-impulse tests. All the impulses were 8/20 μs. The 11 parts of the test gradiently increased the stresses applied to the SPD. This was accomplished by raising the amplitude of the currents (Ipeak), increasing the # of impulses in the sequence, and decreasing the intervals between strokes. More on multiple impulse testing can be found here.

The Astounding Results

Three SPD brands fell by the wayside by the 3rd sequence of impulses (30kA Ipeak.) The entries of seven more manufacturers were destroyed by the 7th sequence. (60kA Ipeak) The performance of the European and the domestic Chinese entries were equally lackluster.

Only one SPD, the American entry, made it through the 7th (60kA) sequence. That same SPD also made it through the 8th, 9th, 10th, and 11th sequences. (100kA Ipeak) Up through the 10th sequence the interstroke interval had been set at 60ms. But on the 11th and final test sequence this was reduced to 30ms. The American entry was the only SPD to be subjected to both the 100kA impulses and the reduced 30ms intervals. In the final sequence of 7 impulses (100kA, 50kA, 50kA, 50kA, 50kA, 50kA, 100kA), one element in the SPD sacrificed itself. By the end of that 11th test, 85% of the SPD’s protection modules had survived intact, thus maintaining the continuity of protection for any downstream electrical equipment. Equally as impressive, the final 100kA impulse was clamped down to 2.2kV (in a 220/380 power system.)

The following chart shows the sequence of 11 tests. The white checkmarks on the left indicate the test sequences passed only by the American SPD.

The reason that one SPD so markedly outperformed all the others is simply that it was designed to protect against lightning parameters consistent with those upheld in CIGRE’s 2013 report. You can find more about those specifications here.

Advice to spark gap manufacturers: Credibility Counts

Here's advice to spark gap manufacturers who may wish to persist in asserting that the 10/350 waveform is the stuff of which lightning is made. (Advice summarized from results of a survey of 2378 victims of the 10/350 waveform.)

"Be aware that from now on, the only way to achieve any credibility for a spark gap product will be to submit it to the Beijing SPD Test Center to undergo the above series of 11 tests. Submit a single-unit spark gap arrestor or any hybrid form of "combination arrestor." You are going to need to prove how well your spark gap products perform in a laboratory test based on the parameters of real lightning (as sanctioned in CIGRE's 2013 report.)

How many of the above 11 test sequences can your spark gap withstand? What protection level will it secure for downstream electronic equipment? Publish the results and then let the customers decide. (Alternatively, just ask Dehn and Söhne how well its entry performed in the 2011 test, take a deep breath, and then move directly to the Spark Gap Challenge in the following section.)"

The 2013 Spark Gap Challenge

Forward-looking spark gap manufacturers will choose to view CIGRE's 2013 report as an opportunity. For those who can see the writing on the wall, here is your challenge: Confront CIGRE's TB 549 findings and realize they mean a phase-out of any SPDs or theories based on a 10/350 waveform. So why not get busy designing and manufacturing SPDs aimed at protection against the characteristics of real lightning? Which of the "Big Three" will be first to take up this challenge and lead the way to a saner, safer surge protective environment? Dehn and Söhne, OBO-Betterman or Phoenix Contact? Remember, the actions you folks take today, will enable customers and design engineers all over the world to sleep more peacefully at night--with one less worry about the safety of their electronic systems.